Electroalfa’s Steel Fabricated Parts Business Unit manufactures standardized enclosures for the electrical cabinets used by Electroalfa’s Electrical Products and provides subcontractor services for companies who market steel parts in small and medium fabrication series.

Investments

We are aware that the efficiency can be obtained only by using the latest manufacturing capabilities.During the last years Electroalfa invested around 5 million euro in the steel parts factory, acquiring new machines and software and extending the production floor with two new halls.

Technologies

The Steel Fabricated Parts factory uses a complete range of industry specific manufacturing technologies:

- › punching

- › laser cutting

- › welding robot

- › bend presses and automated bending centres

- › powder painting

- › gasketing

- › electrochemical plating

Wide experience on the design and production of steel

Complete control of the specific processes by Oracle based ERP and MRP customized software solutions

High standard of quality assurance – ISO certification welding certification acc. EN 15085-2 CL1

Advanced technological capabilities

Speed and versatility in meeting customer requests

Competitive price/quality ratio

Design and testing capabilities within the in-house Research and Development Center

Partnerships with reputable technical universities

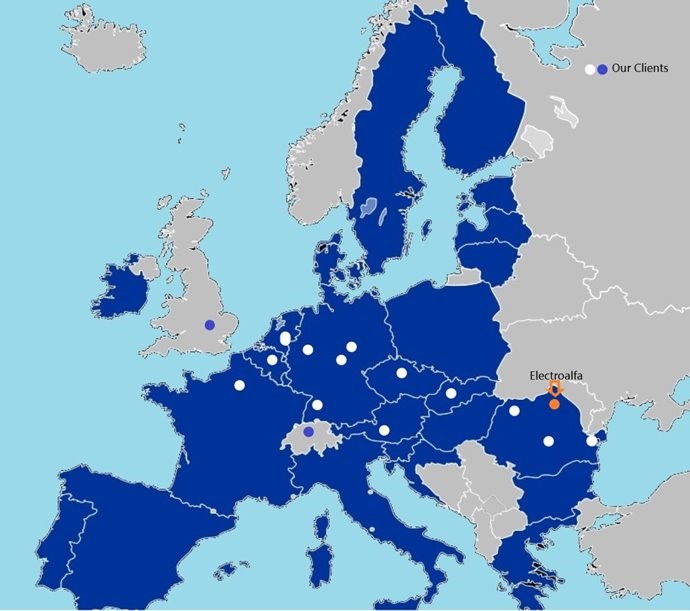

International experience in logistics and supply chain

REFERENCES

Electric equipment

- Enclosures for electrical application

Renewable energy and energy storage

- Switchboards and enclosures for wind turbines

- Energy storage and management cabinets

- EV charger cabinets

Railway

- Enclosures for traction converters, battery, transformers

- Cabinet for railway infrastructure

Industry

- Cabinets for heavy cranes

- Control cabinets for plastic injection

- Cabinets and parts of machine tools

Shipbuilding

- Low voltage switchboards

Other sectors

- Acoustic booths